News

Common Types of Punching Equipment

A punching machine, also known as a stamping press, is a versatile tool used in the manufacturing process to create parts through various processes such as blanking, punching, forming, drawing, trimming, fine punching, shaping, riveting, and extrusion. Stamping, through the use of molds, has many advantages in production, including material and energy savings, high efficiency, and low technical skill requirements for operators. It also allows for the creation of intricate components that cannot be achieved with traditional mechanical processing.

Punching machines are widely used across many industries, from everyday products like switches, sockets, and computer cases to more complex applications in the aerospace and automotive industries. The variety of parts produced by punching machines is vast, with molds enabling the production of everything from household items to high-performance components. Below, we explore the common types of punching machines used in manufacturing.

Types of Punching Machines Based on Drive Mechanism

Types of Punching Machines Based on Drive Mechanism

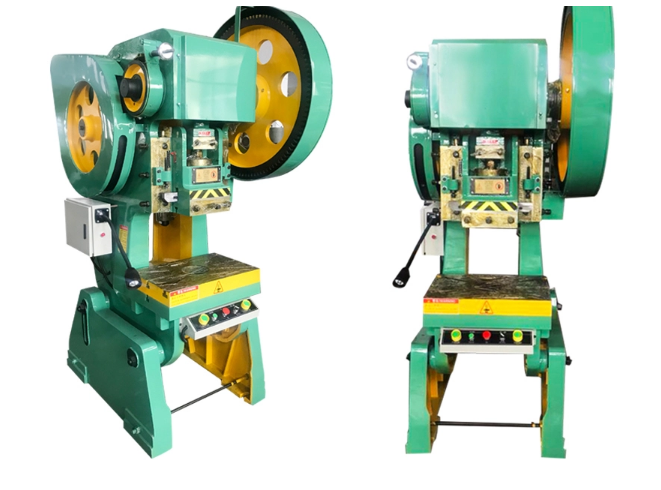

Mechanical Punching Machine

Mechanical punching machines are commonly used for standard sheet metal stamping processes. These machines operate through a mechanical drive, typically using a flywheel or motor to create the necessary force to perform stamping operations. These are widely used in many industrial applications due to their reliability, speed, and relatively simple design.

Hydraulic Punching Machine

Hydraulic punching machines utilize hydraulic power to apply force, making them suitable for heavier-duty applications. Hydraulic machines offer greater flexibility and can handle more complex punching tasks. They are classified into oil-type and water-type punching presses, with oil-type machines being more common. Water-type punching presses are typically used for large-scale, specialized machinery.

Classification by Slider Movement

Classification by Slider Movement

Single-Action Punch Press

The most common type of punching press is the single-action punch press, which features one slider. This simple design is suitable for a wide range of applications, such as blanking, punching, and simple forming processes. It is the go-to choice for general punching operations due to its reliability and versatility.

Double-Action and Triple-Action Punch Presses

Double-action and triple-action punch presses feature two or three sliders, respectively. These presses are generally used for more complex processing, such as in the automotive industry for forming large or intricate parts. Due to their complexity, these machines are less common than single-action presses and are typically used in specialized applications.

Classification by Slider Drive Mechanism

Classification by Slider Drive Mechanism

Crankshaft Punch Press

A crankshaft punch press uses a crankshaft mechanism to drive the slider. This design is the most common in punching machines due to its simple construction and reliable operation. It is suitable for a wide range of stamping processes, including punching, bending, stretching, hot forging, cold forging, and other common punching operations. The crankshaft design ensures accurate stroke positioning, making it ideal for general use in various industries.

Crankless Punch Press

Also known as an eccentric gear punch press, this machine utilizes an eccentric gear system instead of a crankshaft to drive the slider. While crankless punch presses offer better shaft rigidity, lubrication, and maintenance compared to crankshaft-based machines, they are typically more expensive. These machines are advantageous for long strokes, but for short strokes, a crankshaft punch press may be a better option, especially for high-speed punching.

Knuckle Punch Press

The knuckle punch press employs a toggle mechanism to drive the slider. This unique design allows for precise control of the slider's motion, particularly at the bottom dead point where the slider slows down significantly. As a result, knuckle punch presses are ideal for compression processes, such as stamping and cold forging, where accuracy is paramount.

Friction Punch Press

Friction punch presses utilize a friction transmission system and a spiral mechanism for slider movement. These machines are versatile and can be used for various processes, including forging, bending, forming, and stretching. Their multi-purpose functionality and relatively low cost have made them popular in many industries.

Screw Punch Press

A screw punch press uses a screw mechanism to drive the slider. While this system is less common than other types, screw punch presses are known for their precision and are used in applications requiring highly accurate punching operations.

Rack Punch Press

Rack punch presses use a rack and pinion mechanism to drive the slider. These machines are similar to screw punch presses but are typically used in older applications. Rack punch presses were historically used for processes like pressing bushings or hot thinning processing but have been largely replaced by hydraulic punch presses in modern manufacturing.

Connecting Rod Punch Press

A connecting rod punch press uses a connecting rod mechanism to drive the slider. The connecting rod system is designed to maintain a consistent stretching speed and reduce the processing cycle, especially during the stretching process. This allows for a faster cycle time compared to crankshaft punch presses, enhancing productivity in high-volume operations.

Cam Punch Press

Cam punch presses use a cam mechanism to control the slider’s movement. The cam system allows for precise control of the slider's activity, ensuring the desired motion for various punching processes. However, due to the limitations of the cam mechanism, cam punch presses are typically used for smaller, less demanding tasks with lower capacities.

Welcome to Order From Us

Welcome to Order From Us

At Jiuying, we specialize in providing high-quality punching machines suited for a variety of industrial applications. Whether you're looking for a mechanical, hydraulic, or specialized punch press, we have the right equipment to meet your needs. With over ten years of experience in the industry, we are dedicated to delivering solutions that improve efficiency, reduce costs, and enhance product quality.

If you’re ready to upgrade your punching equipment or need expert guidance in selecting the right machine for your business, don’t hesitate to reach out to us. We look forward to helping you optimize your manufacturing processes and achieve your production goals.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China