News

Get to Know J&Y Aluminum Foil Lunch Box Production Line

An aluminum foil production line involves a series of essential processes and equipment to transform raw materials into finished aluminum foil products. It begins with melting high-quality aluminum ingots in a furnace and casting them into large slabs or billets, which are then hot rolled into thin sheets. Cold rolling further reduces the thickness to the desired gauge, followed by annealing to improve ductility.

The sheets undergo foil milling to achieve precise thickness and surface finish, and are slit into various widths. Surface treatments like coatings or finishes may be applied as needed. Quality control ensures consistency in thickness, strength, and surface quality throughout production. Finally, the finished aluminum foil rolls are cut, packaged, and prepared for distribution, supported by automation systems to monitor and optimize the manufacturing process while minimizing environmental impact through waste recycling efforts.

Aluminum Foil Lunch Box Production Flow

Aluminum Foil Lunch Box Production Flow

1. Raw Material Preparation: The production begins with the preparation of high-quality aluminum alloy coils. These coils are cleaned to remove contaminants and pre-treated to enhance their surface properties, ensuring the aluminum is suitable for producing durable and hygienic lunch boxes.

2. Rolling Process: The aluminum coils undergo a rolling process to reduce their thickness. This involves hot rolling at high temperatures followed by cold rolling to further decrease thickness and improve the material's strength and finish. This ensures the aluminum foil is strong and flexible, meeting the requirements for lunch box production.

3. Annealing and Foil Rolling: Annealing, a heat treatment process, softens the aluminum sheets, making them more workable. The annealed sheets are then rolled into thin foils through a series of rolling mills, with precise thickness control and lubrication to enhance the quality of the final product.

4. Forming and Trimming: The aluminum foil is cut and slit into desired widths and lengths. The cut sheets are fed into forming machines where they are molded into the shape of lunch boxes using high-pressure stamping. Excess material is trimmed off, and the edges are smoothened to ensure a safe and uniform finish.

5. Surface Treatment and Quality Control: Surface treatment processes, such as anodizing, enhance the appearance and durability of the lunch boxes. Rigorous inspection and quality control are conducted to identify and eliminate defects, ensuring only high-quality products reach the market.

6. Packaging and Distribution: Before packaging, the lunch boxes may undergo sterilization to ensure they are hygienic. The final products are carefully packed into cartons or boxes to prevent damage during transportation and storage. The packed aluminum foil lunch boxes are then distributed to retailers, wholesalers, or directly to customers, ensuring timely delivery and customer satisfaction.

Requested Equipment in Aluminum Foil Lunch Box Production Line

Requested Equipment in Aluminum Foil Lunch Box Production Line

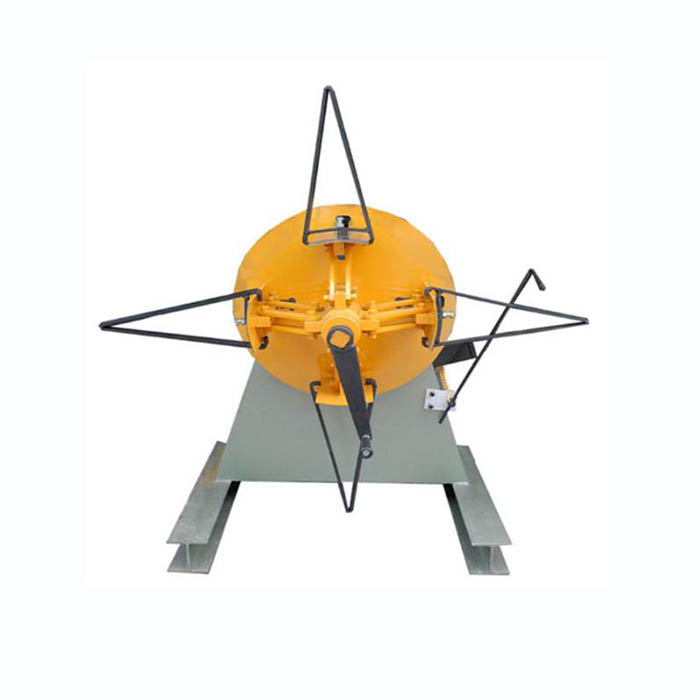

Auto Feeder

The auto feeder is a crucial component in the aluminum foil food container production line. It automatically feeds aluminum foil sheets into the stamping or punching press machine. This equipment ensures a continuous and efficient supply of foil, optimizing production throughput and reducing manual handling.

Auto Stamping Punching Press Machine

The auto stamping punching press machine is used to precisely shape and form aluminum foil sheets into food containers. It operates automatically, applying high-pressure stamping to cut and mold the foil into the desired container shapes. This machine ensures consistent quality and high production efficiency in forming various sizes and types of food containers.

Auto Box Packed Machine

The auto box packed machine is responsible for packaging the finished aluminum foil food containers into boxes or cartons. It automates the process of placing containers into packaging materials, ensuring proper arrangement and secure packaging for transportation and storage. This equipment plays a crucial role in maintaining product integrity and efficiency in the packaging stage of production.

Auto Waste Recycling Equipment

The auto waste recycling equipment is integral to the sustainability of the production line. It automatically collects and processes waste generated during the manufacturing process of aluminum foil food containers. This equipment typically includes compactors, shredders, and recycling units that efficiently handle and recycle aluminum waste, contributing to environmental sustainability and reducing production costs.

Advantages of Our Aluminum Foil Lunch Box Production Line Equipment

Advantages of Our Aluminum Foil Lunch Box Production Line Equipment

Our aluminum foil production line offers distinct advantages that set us apart in the industry. With state-of-the-art facilities and advanced technologies, we ensure precision and consistency in every step of the manufacturing process. Our expertise in metallurgy and materials science allows us to produce high-quality aluminum foil with superior strength, thickness control, and surface finish. Rigorous quality assurance protocols guarantee that our products meet or exceed international standards for various applications, from food packaging to industrial uses.

We prioritize sustainability through efficient resource management and waste reduction strategies, underscoring our commitment to environmental responsibility. Combined with responsive customer service and a dedication to innovation, we deliver reliable solutions that meet the diverse needs of our global clientele.

Why Choose Us

Why Choose Us

Choose us for your aluminum foil needs because we offer a compelling combination of expertise, reliability, and innovation. Our state-of-the-art production facilities ensure that we consistently deliver high-quality aluminum foil products that meet stringent industry standards. We prioritize customer satisfaction through responsive service and flexible solutions tailored to your specific requirements.

Our commitment to sustainability means that we employ eco-friendly practices throughout our manufacturing process, minimizing environmental impact. With a dedicated focus on innovation and continuous improvement, we strive to stay ahead in technological advancements and product development, ensuring that you receive cutting-edge solutions for your packaging and industrial needs. Partnering with us means choosing a trusted ally in aluminum foil production, dedicated to quality, sustainability, and customer-centric innovation.

Contact Us

Contact Us

Feel free to reach out to us for any inquiries related to aluminum foil production equipment or other relevant matters.

Contact: Mr Liu (manager)

Whatsapp/Mob/Wechat: 008613394110095

Email: liu@weldcnc.com

Website: www.weldcnc.com

Address: 20# Ganwang Street, Dalian City, Liaoning Province, China

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China