News

Plasma Cutting Machines: A Quick Guide

When considering the purchase of a plasma cutting machine, it's essential to keep your budget in mind. Domestic models come in low, medium, and high-power specifications, offering a more affordable range of options. These machines typically deliver good performance at a reasonable cost. On the other hand, imported plasma cutting machines, while known for their superior cutting results, can be several times more expensive, especially when factoring in the high cost of consumables such as nozzles and electrodes. It's important to strike a balance between cost and performance, ensuring the machine you choose fits both your budget and production needs.

Cutting Thickness

Cutting Thickness

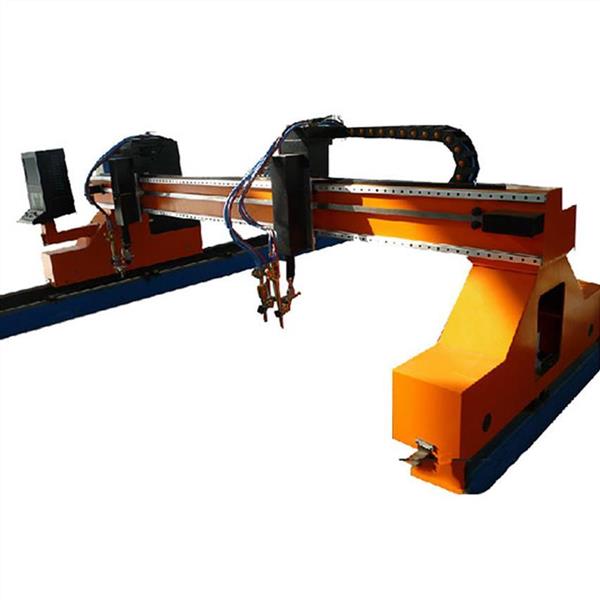

Plasma cutting machines are designed to handle various material thicknesses, making it important to select the right machine for your specific application. For cutting thin plates, typically under 2mm, low-power plasma machines are highly effective. Portable and gantry models are suitable for cutting steel plates in the 2mm to 16mm range, offering good flexibility and performance. For materials over 25mm thick, gantry models excel, as they provide the necessary power and precision to handle heavy-duty cutting jobs. Understanding the thickness requirements of your materials will help you choose the most suitable machine.

Cutting Materials

Cutting Materials

Plasma cutting is particularly effective for processing stainless steel and a range of alloy materials, which makes it a valuable tool in industries such as automotive, aerospace, and metal fabrication. While carbon steel can often be cut using flame cutting techniques, plasma cutting is essential for stainless steel. The ability to cut stainless steel quickly and precisely is one of the key advantages of plasma cutting machines, allowing for cleaner cuts and better overall performance in metal processing applications.

CNC Plasma Cutting Advantages

CNC Plasma Cutting Advantages

CNC plasma cutting offers several key advantages that make it a superior choice for many metal cutting applications. One of the primary benefits is its ability to produce minimal dross on the cut edges. Compared to flame cutting, which often results in iron red dross, plasma cutting creates less waste, which is easier to remove. Additionally, the heat-affected zone (HAZ) is significantly smaller with plasma cutting, which reduces the need for post-processing and additional welding. CNC plasma cutting is also much faster than flame cutting—up to 8.5 times faster—leading to higher productivity and shorter cycle times. With its speed and efficiency, CNC plasma cutting lowers the overall cost per part, making it a cost-effective choice for high-volume production.

Maintenance Tips

Maintenance Tips

Proper maintenance is crucial to keeping your plasma cutting machine in peak operating condition. First, ensure that all consumables, such as electrodes, nozzles, and swirl rings, are replaced before they wear out completely. Allowing these parts to wear too long can lead to uncontrollable plasma arcs, which can damage the cutting torch. Regularly clean the cutting torch, including its connecting threads, to ensure proper airflow and functionality. Additionally, always check the gas and cooling air flow before starting a job. Any leaks or insufficient flow should be addressed immediately to prevent damage to the machine. Finally, program the system to avoid collisions and consider installing an anti-collision device to further protect your investment.

Common Torch Damage

Common Torch Damage

Cutting torch damage can occur for several reasons, most commonly due to torch collisions, wear from damaged consumables, or contamination by dirt. If consumables such as electrodes and nozzles are worn out or dirty, they can cause unstable arcs, which can lead to damage to the torch and other parts of the system. Loose parts, improper settings, or incorrect installation can also contribute to instability. Regular maintenance and inspections are essential for minimizing the risk of torch damage and maintaining optimal cutting performance.

Why Choose Us

Why Choose Us

With over ten years of experience in the plasma cutting industry, we are committed to providing high-quality, tailored solutions to meet your specific needs. Our plasma cutting machines are designed for precision and efficiency, offering superior performance for a wide range of cutting applications. We understand the importance of reliability in your operations, which is why we offer 24/7 online support and a one-year warranty on all our equipment. Trust us to provide the best equipment, backed by expert service, to enhance your cutting processes and boost your productivity.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China