News

Advanced Machinery: Efficiency in Light Pole Production

In the realm of urban infrastructure, light poles serve as essential elements, providing illumination and enhancing safety throughout cities and towns. Behind the scenes, the production of these vital fixtures relies on advanced machinery designed to optimize efficiency and ensure top-quality results. Let's explore some of the key machines that drive the light pole production process:

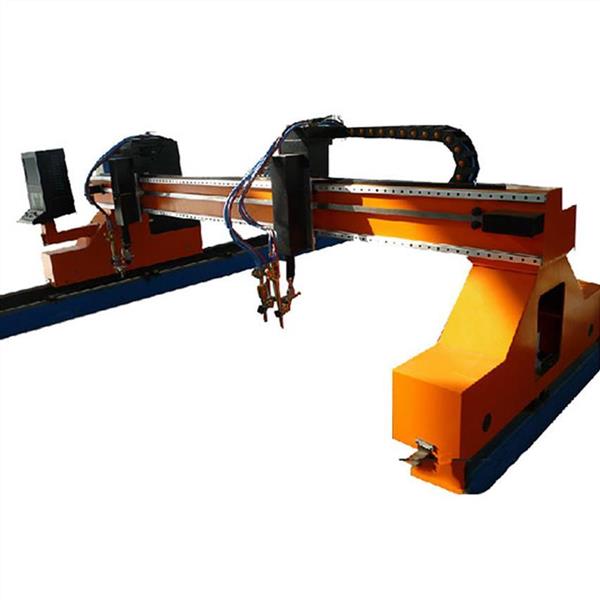

CNC Flame & Plasma Cutting Machines

CNC Flame & Plasma Cutting Machines

Jiuying

CNC flame and plasma cutting machines are pivotal in shaping the initial components of light poles from raw materials such as steel. These machines use computer-guided precision to cut through thick materials with ease, ensuring accurate shapes and dimensions for various pole designs.

Auto Beveling Machines

Auto Beveling Machines

Jiuying

Preparing materials for welding demands precise beveling to ensure strong and seamless joints. Auto beveling machines automate this critical task, efficiently creating beveled edges on poles and components. This automation not only accelerates production but also enhances the consistency and quality of welds.

CNC Dual Linkage Hydraulic Press Brake

CNC Dual Linkage Hydraulic Press Brake

Jiuying

When it comes to forming and bending metal components for light poles, precision is paramount. CNC dual linkage hydraulic press brakes excel in this role, offering precise control over bending angles and ensuring uniformity across production batches. These machines accommodate a range of pole designs and thicknesses with efficiency and reliability.

Gantry Type Hydraulic Seam Assembled Machine

Gantry Type Hydraulic Seam Assembled Machine

Jiuying

Assembling light pole sections requires robust machinery capable of handling large structures with precision. Gantry type hydraulic seam assembled machines facilitate the alignment and joining of pole sections, ensuring tight seams and structural integrity. These machines streamline the assembly process, reducing labor costs and minimizing assembly time.

Gantry Type Large Diameter Submerged Arc Welding Machine

Gantry Type Large Diameter Submerged Arc Welding Machine

Jiuying

Welding plays a crucial role in the durability of light poles, especially for joints and seams. Gantry type large diameter submerged arc welding machines specialize in welding large diameter poles with submerged arc welding techniques. These machines offer high deposition rates and excellent penetration, resulting in strong, reliable welds that withstand outdoor conditions.

Single Arm Internal Seam Welder

Single Arm Internal Seam Welder

Jiuying

Internal welding of light pole sections requires precision and accessibility. Single arm internal seam welders are designed to weld inside the poles with accuracy, ensuring uniform weld beads and consistent quality throughout. These machines are essential for maintaining the structural integrity and longevity of the finished poles.

How Do These Equipments Work?

How Do These Equipments Work?

Jiuying

CNC flame and plasma cutting machines use computer control to precisely cut steel plates into shapes needed for light pole components, whether through oxygen-fueled flame cutting or plasma arcs. Auto beveling machines automate the creation of angled edges on metal, crucial for strong weld joints. CNC dual linkage hydraulic press brakes bend metal sheets with precision, forming components like pole brackets. Gantry type hydraulic seam assembled machines align and join large pole sections efficiently. Gantry type large diameter submerged arc welding machines weld poles with protective flux for durability. Single arm internal seam welders ensure strong internal welds, vital for pole integrity. These machines collectively optimize production, ensuring high-quality, resilient light poles for urban settings.

Why Choose Us

Why Choose Us

Jiuying

Choose us as your partner for light pole production line equipment because we offer comprehensive solutions that span the entire manufacturing process. From precision CNC cutting and bending to advanced welding and assembly systems, our equipment ensures efficiency, quality, and reliability at every stage. Backed by our expertise and commitment to innovation, we deliver integrated solutions that meet the rigorous demands of urban infrastructure projects. Count on us to equip your production line with the tools necessary to achieve superior results and drive success in light pole manufacturing.

Contact Us To Order

Contact Us To Order

Jiuying

To streamline your light pole production with our advanced equipment, contact us today to place your order. Benefit from our expertise in CNC cutting, bending, welding, and assembly technologies, ensuring efficient manufacturing and superior product quality. Reach out to us now to discuss your specific requirements and start enhancing your production capabilities.

Contact: Mr Liu (manager)

Whatsapp/Mob/Wechat: 008613394110095

Email: [email protected]

Website: www.weldcnc.com

Address: 20# Ganwang Street, Dalian City, Liaoning Province, China

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:[email protected]

Add:20# Ganwan Street, Zhongshan District, Dalian City, China