News

Comprehensive Guide to Steel Door Production Line Machinery

Steel doors have become synonymous with security, durability, and modern aesthetics. To meet the growing demand, advanced steel door production line machinery has evolved, integrating cutting-edge technology and efficient processes. This article delves into the intricacies of steel door production line machines, with a special emphasis on the hydraulic steel door embossing machine, highlighting its components, functionalities, and benefits to manufacturers.

Introduction to Steel Door Production Line Machinery

Steel door production line machinery encompasses a series of automated and semi-automated equipment designed to fabricate steel doors from raw materials. These machines are engineered to handle various processes such as cutting, bending, welding, painting, and assembling, ensuring high precision and consistency in production.

Our products include:

Hydraulic Steel Door Embossing Machine: The Heart of the Production Line

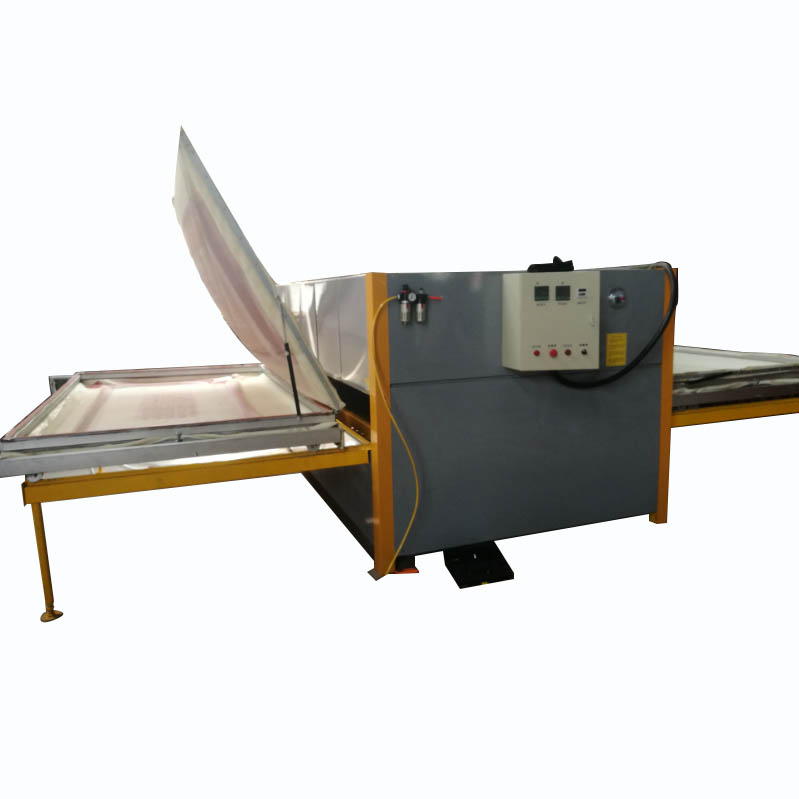

The hydraulic steel door embossing machine is arguably the most crucial piece of equipment in the steel door production line. This machine is responsible for creating intricate patterns and designs on the door surfaces, which not only enhance the aesthetic appeal but also add to the structural integrity of the doors.

The hydraulic embossing machine uses high pressure to press detailed designs into steel sheets. It typically consists of a hydraulic press system, embossing dies, and a control system. The hydraulic system provides the necessary force, while the embossing dies, which can be customized to various patterns, shape the steel sheet. The control system, often computerized, allows for precise adjustments and consistency in the embossing process.

Key Components of Steel Door Production Line Machinery

In addition to the embossing machine, our production line includes several other critical machines. The automatic door frame forming line is essential for shaping steel sheets into door frames. This line features advanced roll forming technology that ensures precise and uniform frame production, accommodating various frame designs and specifications.

The transfer machines are pivotal for moving materials seamlessly between different stages of the production process. These machines enhance workflow efficiency and reduce manual handling, ensuring a smooth and continuous production line.

Our foam laminating machines are designed to enhance the insulation properties of steel doors. These machines apply foam layers to the steel sheets, providing superior thermal and acoustic insulation, which is crucial for modern building requirements.

Benefits of Modern Steel Door Production Line Machinery

Enhanced efficiency is one of the primary benefits of modern steel door production line machinery. Automated processes significantly reduce production time and labor costs, while high-speed operations increase throughput to meet high demand.

Consistency in quality is another significant advantage. Precision engineering ensures that every door produced adheres to strict specifications, minimizing defects and ensuring uniformity. Advanced controls in the machinery further reduce human error, leading to higher quality products.

Flexibility is also a key benefit. CNC and programmable machines allow manufacturers to make easy adjustments and customizations, making it possible to produce a wide range of door designs and specifications. This adaptability is essential for meeting diverse customer needs.

Cost-effectiveness is achieved through reduced waste and efficient material usage. In addition, the automation of labor-intensive tasks and reduced maintenance costs contribute to long-term savings. These factors make modern machinery a wise investment for manufacturers.

Safety is paramount in these production lines. Integrated safety features protect operators, reducing the risk of accidents. Automation also minimizes the need for hazardous manual tasks, creating a safer working environment.

Innovations in Steel Door Production Line Machinery

Recent advancements have brought about several innovations in steel door production. Smart manufacturing integrates IoT (Internet of Things) for real-time monitoring and control, allowing for predictive maintenance using data analytics to minimize downtime and enhance efficiency.

Eco-friendly solutions are increasingly adopted, with energy-efficient machines and processes reducing environmental impact. The use of eco-friendly coatings and materials further enhances sustainability in production.

Advanced robotics have revolutionized handling and assembly processes. Robotic arms provide precision in intricate tasks and automate repetitive operations, improving both efficiency and consistency in production.

Customization and modularity are also on the rise. Machines designed for easy changeovers and customization enable manufacturers to adapt quickly to different production requirements. Modular designs allow for scalable production lines, accommodating growth and changes in demand.

Customer-Centric Approach

We are committed to a customer-centric approach, providing a full range of pre-sales consultation, sales support, and after-sales services. Our dedicated team ensures that customers receive the highest level of service and support throughout the cooperation process. From initial consultation to post-purchase assistance, we strive to exceed customer expectations and build lasting partnerships.

As technology continues to evolve, manufacturers can expect even greater innovations that will further revolutionize the steel door production industry. By embracing these advancements, manufacturers can meet the increasing demand for steel doors while maintaining a competitive edge and sustainability in the market.

Contact Us

Whatsapp/Mob/Wechat: 008613394110095

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China