News

Production process flow of Jco pipe production line

Jco pipe production line is also known as large diameter pipe production line, straight seam submerged arc welded steel pipe production line, and LSAW steel pipe production line. The production line adopts JCO (J-ing, C-ing, O-ing) process, which has the characteristics of high forming precision, high forming efficiency and uniform forming stress distribution. Mainly used in heavy steel structure engineering and fluid pipeline engineering, foundation piling engineering.

Jco pipe production line production process

Main products and functions:

1. Edge milling machine: The main function is to cut the sheet, remove the burr, and correct the size of the sheet. As a substitute for edge planing machine, edge milling machine has the advantages of high efficiency, high precision and low energy consumption. It is especially suitable for the beveling of various shapes of carbon steel plates. Generally 6-80mm thickness, 0-60 degrees can be adjusted arbitrarily.

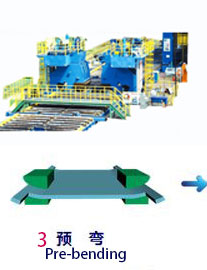

2. Pre-bending machine: The pre-bending machine is a fully automatic forming roller rolling and bending machine for steel plates, which can avoid the "peach-shaped" phenomenon of the tip of the steel pipe product, so that the diameter of the steel pipe after the "O" type process, The roundness is closer to the precision required by the product technology, and the pre-formed steel plate has a small springback, fast forming speed and high efficiency.

3. Bending machine (JCO gantry bending machine): The JCO (J-ing, C-ing, O-ing) process is used to bend the sheet, which has fast forming, more accurate precision and high manufacturing efficiency.

4. Steel pipe welding machine: Preliminarily weld the folded steel pipe to avoid deformation and prepare for the subsequent process.

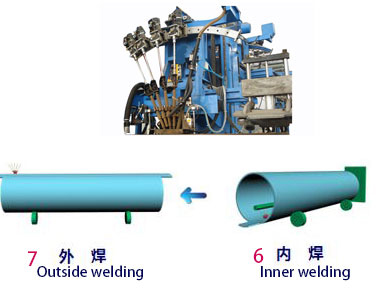

5. Internal welding and external welding machine: As the name implies, it welds the folded steel pipe joints, and welds them from the inside to the outside and from the outside to the inside, so that the welding is stronger, and it is not easy to deform and leak.

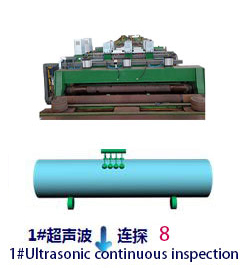

6. Ultrasonic inspection: It is an instrument that uses ultrasonic waves to detect whether there are defects inside the object. It can detect defects, locate defects, evaluate defects and diagnose defects. It uses ultrasonic inspection machines to detect whether there are problems in steel pipes and repair them in time. .

7. X-ray inspection machine: use X-ray to detect the welding condition of the steel pipe weld, whether there is any external problem, and deal with it in time.

8. Diameter expander: Unify the diameter of the pipeline through the expansion machine, making the pipeline more standard and beautiful.

9. Back bending machine: There are two straight sides of the open steel pipe after bending. This machine mainly rolls the straight side of the open steel pipe into an open steel pipe that meets the required roundness.

10. Hydraulic testing machine: Detect the compressive strength and tightness of the pipeline, improve the stress distribution and stress condition and find defects.

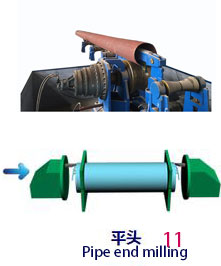

11. Pipe end beveling machine: The pipe end beveling machine is a special tool for chamfering and beveling the pipe or flat plate on the front face of the welding, which solves the irregular angle and slope of the flame cutting, grinding machine grinding and other operating processes. It has the disadvantages of roughness and large working noise, and has the advantages of easy operation, standard angle and smooth surface.

The above is the main machine and operation process of the JCO pipe production line to manufacture JCO pipes. All the machines can be purchased separately. If you want to know about this production line or a certain machine, you can contact us directly and look forward to your reply.

CATEGORIES

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:[email protected]

Add:20# Ganwan Street, Zhongshan District, Dalian City, China