Electric water heater production line machines and equipments

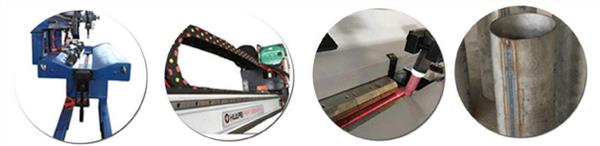

Longitudinal seam welding machine of electric water heater production line

Longitudinal seam welding machine of electric water heater production line is used to weld the vertical seam of the cylinder to the vertical seam of the plate. Suitable for welding methods such as autolysis (wire filling) for gas shielded welding and argon arc welding. The workpiece is compressed by the airbag-type mechanism, and the entire range of the workpiece is fully contacted with the welded copper strip after compaction, so as to realize single-sided welding and double-sided forming to ensure the welding quality. It has a shielding device to protect the workpiece from deformation during the welding process, and the shape of reverse welding is beautiful. The equipment adopts PLC control to realize automatic welding operation!

Features of straight seam welding machine:

1. The straight seam welding adopts a keyed copper alloy pressing mechanism to provide uniform and stable workpiece clamping and cooling effects;

2. Equipped with post-welding protective bushing and forming groove to ensure stable gas protection, and has the perfect effect of single-sided welding and double-sided forming;

3. The machine can choose PLC or relay integrated control as needed;

4. The welding torch is driven by a DC motor, and the welding speed is steplessly adjustable.

5. Can match any type of arc welding power source (argon arc/CO2 welding/plasma arc welding);

6. The humanized design of the equipment can only be operated by ordinary workers, which solves the difficulty of recruiting workers in the factory, the difficulty of recruiting welding masters, and the low production efficiency;

7. Automatic straight seam welding is mainly used for high quality and low deformation automatic straight seam welding of stainless steel, iron, aluminum, brass and other metal cylinders and assembly plates.

CATEGORIES

- Kitchen sink/wash basin production line machines and equipments

- Wheelbarrow/trolley production line machines and equipment

- Aluminum foil food container production line machines and equipment

- JCO pipe production line machines/equipments

- Light pole/power pole/communication tower pole production line machines and equipments

- Water tank/Oil tank/Fuel tank production line machines/equipments

- Pressure vessel production line machines/equipments

- LPG gas tank/cylinder production line machines/equipments

- Sieve production line machines/equipments

- Electric water heater production line machines and equipments

- H-beam profile production line machines and equipments

- Steel door production line machines and equipments

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:[email protected]

Add:20# Ganwan Street, Zhongshan District, Dalian City, China