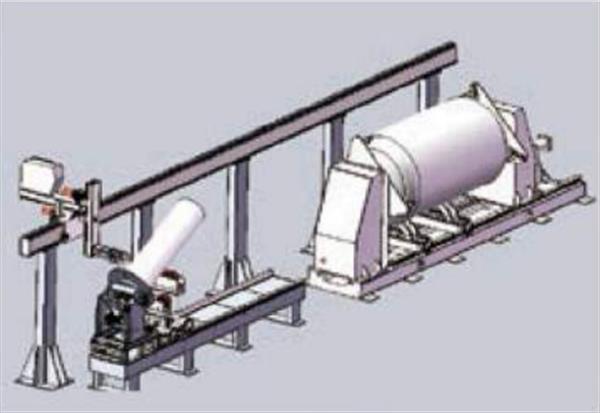

Pressure vessel production line machines/equipments

Circular seam weding machine of pressure vessel production line

Circular seam weding machine of pressure vessel production line

Circular seam weding machine of pressure vessel production line is a kind of universal automatic girth welding machine, which is applicable to a wide range.

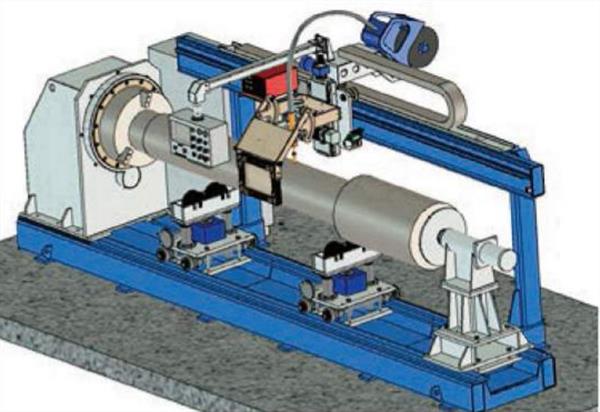

Circular seam weding machine of pressure vessel production line horizontal bed, with adjustable rotating head, pneumatic tail seat and x-Y two-axis electric towing plate.

The rotating head can be turned up and down 90 degrees. In addition to normal horizontal welding, vertical welding can also be carried out. The spindle of the head is driven by servo motor, which can set the welding speed and weld overlap Angle.

The welding gun is fixed on the gun rack of the electric towing plate. The Angle of the welding gun can be adjusted at any time, and there is pneumatic gun lifting mechanism.

The two-axis electric towing plate is driven by linear guide rail, precise ball screw and stepping motor, and it is equipped with a numerical control system with all-Chinese man-machine dialogue and programming, which is simple in operation and powerful in function.

Automatic argon arc welding, CO2 shielded welding, MIG/MAG automatic welding can be realized for regular circular seam, straight seam and various special-shaped welds.

Circular seam weding machine of pressure vessel production line is mainly used for the butt welding of carbon steel and stainless steel circular workpieces. Single seam or double seam can be selected according to specific requirements.

Compared with vertical circular seam welder, there is no excessive limit on the length of welders. Three or four meters of long pipe can be easily welded.

The equipment can be widely used in the welding of hydraulic cylinders, automobile direction racks, transmission shafts, gas storage cylinders, chemical and medical containers, liquefied gas tanks, fire-fighting equipment, drums and liquid storage cylinders used in mines and production lines.

Main function and application of Circular seam weding machine of pressure vessel production line

1. Automatic argon arc (plasma) girth welding machine is mainly composed of specially designed girth mechanical automation part and standard power supply part.

2. Depending on the specific welding parts, the mechanical automation part includes: horizontal circular seam automation and vertical circular seam automation.

Specially designed and manufactured by our company.

3. Standard power supply includes: TIG (tungsten gas shielded arc welding), MIG(inert gas shielded arc welding), MAG (active gas shielded arc welding), SAW (submerged arc welding), PAW (plasma welding), etc.

It can be equipped with the high quality standard power supply made by our company. At the same time, customers can also use the power supply of other famous brands first, which has strong universality.

4. The workpiece rotation is driven by the frequency conversion motor + reducer + three claws clamped, the motion is stable, stepless speed regulation.

5. The pressing shaft is driven by cylinder to tighten, loosen and advance and advance of welding gun, and the welding gun has a precise micro-adjusting mechanism, so that the welding gun and the welding seam can form the best orientation.

6. The control system adopts microcomputer integrated control, small volume, reliable and simple operation interface, easy to modify and maintain.

Main technical parameters of Circular seam weding machine of pressure vessel production line

额定输入电源 | Input power supply | 220V/380V/440V/480V, 50/60Hz | |

电机功率 | Motor power | 50W-1500W | |

气源压力 | Gas source pressure | 0.4-0.6Mpa | |

最大焊接工件直径 | Max welding diameter | 488mm | |

焊接速度 | Welding Speed | 200-1000mm/min |

CATEGORIES

- Kitchen sink/wash basin production line machines and equipments

- Wheelbarrow/trolley production line machines and equipment

- Aluminum foil food container production line machines and equipment

- JCO pipe production line machines/equipments

- Light pole/power pole/communication tower pole production line machines and equipments

- Water tank/Oil tank/Fuel tank production line machines/equipments

- Pressure vessel production line machines/equipments

- LPG gas tank/cylinder production line machines/equipments

- Sieve production line machines/equipments

- Electric water heater production line machines and equipments

- H-beam profile production line machines and equipments

- Steel door production line machines and equipments

News

Contact Us

Tel:0086-13394110095

Fax:0086-411-39015062

Phone:0086-13394110095

Email:[email protected]

Add:20# Ganwan Street, Zhongshan District, Dalian City, China